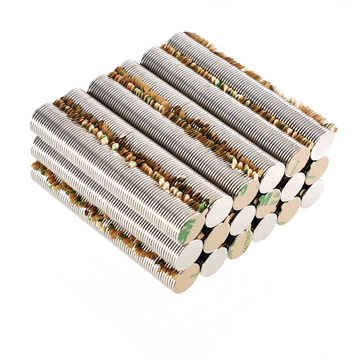

Self Paste Type Thin Magnet

| Payment Type: | L/C,T/T,Paypal,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,FCA,CPT |

| Min. Order: | 2 Piece/Pieces |

| Delivery Time: | 20 Days |

| Packaging: | standard for sea and air delivery |

|---|---|

| Productivity: | 1000000/ month |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | NINGBO |

| Certificate: | ISO9001,Rohs, CE |

Click on the follow link to find out more information: https://www.shinemagnets.com/neodymium-magnet/

Company Info

- Company Name: NINGBO SHINE MAGENETIC TECHNOLOGY CO.,LTD

- Representative: Mr.Sun

- Product/Service: NdFeB Magnet , Precast Concrete Magnet , Shuttering Magnet , Neodymium Magnet , Pot Magnet , Magnetic Assemblies

- Capital (Million US $): 1200000

- Year Established: 2001

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 51% - 60%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 5

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: No.55-58, Gongmao Second Road,Jishigang Industrial Park, Haishu, China

- Contact Person: Mr. sales

- Tel: 86-574-82815633

Premium Related Products

Other Products

Hot Products

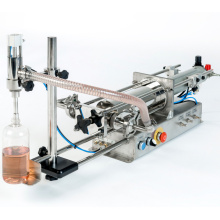

Three Side Seal Trailer Type Vertical Packaging Machine2016 Hot Sale Sachet Coffee and Suguar Horizontal Packing MachineVffs Horizontal Self-Support Bag Packing Machine (AH-180)Ah-500 Auto-Horizontal Pillow Packing MachineChain Bucket Packing Machine Semi-Automatic Packing MachineAutomatic Bread Cake Pillow Packing MachineAh-H100 Trough-Shaped Mixer Machine / (AH-H100)Ah-Cxj24 Bottle Washing Machine (AH-CXJ24)Automatic Powder Packing Machine (AH-FJJ300)Automatic Liquid Filling Packing Machine Beverage MachineAutomatic Ketchup Packing Machine Three Sides Sealing Machine (AH-BLT100)Automatic Semi-Fluid Packing Machine (AH-BLT-500)Automatic Powder Packing Machine, Flour Filling Machine (AH-FJJ100)Automatic Center Seal Bag Beans Packing Machine (AH-KLJ100)Automatic Water Pouch Packing Machine (AH-ZF1000)Automatic Sugar Stick Packing Machine (AH-KLJ100)