The gel filling machine uses imported 316L stainless steel pump head, which has high speed, high precision, corrosion resistance, acid and alkali resistance, and long service life

Factory spot 3ml dishwashing automatic gel liquid filling machine

Product Description

Factory spot 3ml dishwashing Automatic gel Liquid Filling Machine

Products Description

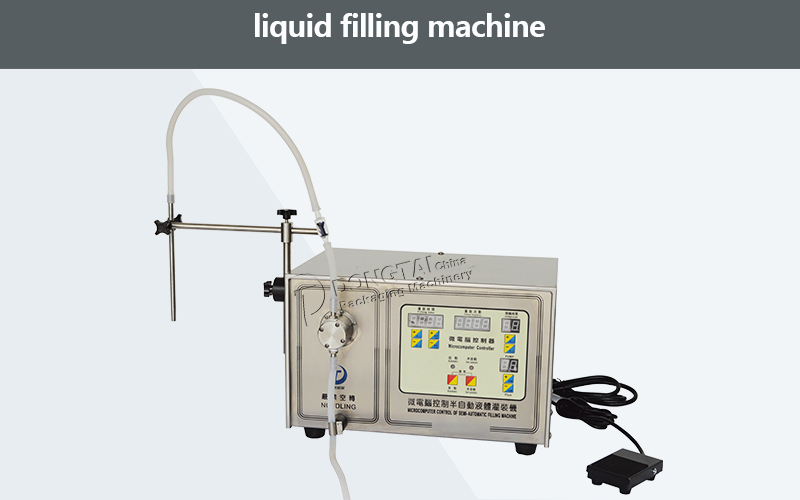

This set of magnetic pump 3ml Filling machine uses a world-brand frequency converter, equipped with imported high-precision multi-turn potentiometers and a lockable dial, so that the flow adjustment is stable and accurate, with a negative deviation of less than 0.5% and a positive deviation of less than 1.5%. Japan imported magnetic gear stainless steel pump, reliable quality and long life. Stainless steel chassis, durable; small size, easy to operate; easy to clean and detoxify; full-featured, automatic and manual. Can be equipped with assembly line work; can be equipped with multiple filling heads, dishwashing liquid filling machine filling volume SF- II is adjustable from 1ml to 10000ml; SF-I is adjustable from 10ml-80000ml, which is convenient to adjust.

product name | 10ml vial Filling Machine | ||||

Model | SF-II-1 | SF-II-2 | SF-II-4 | ||

Rated voltage | AC 220V /±5% | AC 220V /±5% | AC 220V /±5% | ||

Power | 40W | (40×2)W | (40×4)W | ||

Weight | 14kg | 18kg | 28kg | ||

Error | ±1.5% | ±1.5% | ±1.5% | ||

Maximum flow / single pump | >1.44L/min | >1.44L/min | >1.44L/min | ||

Machine size | 410×330×270(mm) | 510×330×270(mm) | 720×330×270(mm) | ||

Packing size | 600×470×365(mm) | 600×470×365(mm) | 810×470×365(mm) | ||

Details Images

Magnetic pump pump head

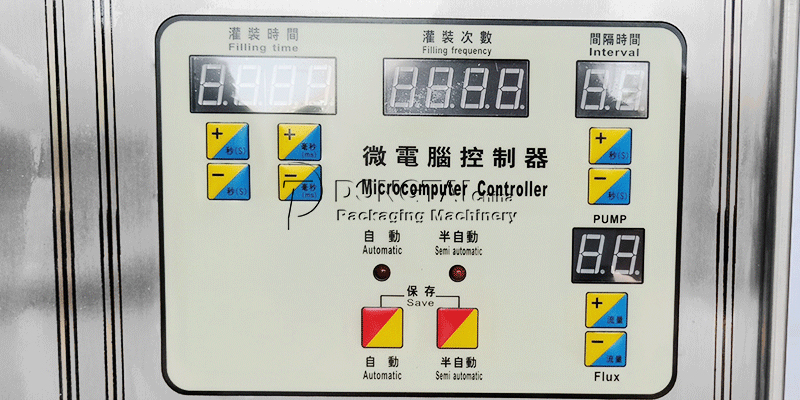

Microcomputer control panel

Imported control four position cursor control board, precise control of 3ml filling machine, intuitive and simple operation, small error;

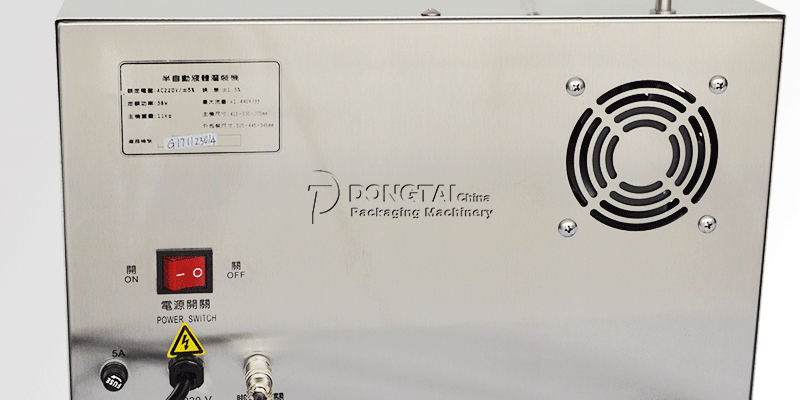

All stainless steel body

The main body of the liquid filling machine is made of stainless steel, which is clean and easy to clean.

3ml filling machine According to the requirements of filling companies, the designers of Dongtai Technology Department divide liquid filling machines into single-head liquid filling machines and double-head liquid filling machines, which are suitable for filling in medicine, daily chemicals, food, pesticides and special industries.

Recommend Products

Company Profile

Shandong Dongtai Machinery Manufacturing Co., Ltd. is located at No. 3843, Airport Road, Lingang Street, High-tech Zone, Jinan City, Shandong Province. It has five companies. Shandong Dongtai Machinery Manufacturing Co., Ltd. is a manufacturer of chemical intelligent equipment. The factory covers an area of 100 acres. It covers an area of 10,000 square meters and has more than 150 employees. It has obtained ISO9001 quality system certification, ISO14001 environmental management system certification, CE certification and a number of invention patents. For more than ten years, Shandong Dongtai Machinery Manufacturing Co., Ltd. has continued to innovate and develop and keep pace with the times. Provided several generations of advanced smart packaging equipment for many companies, and established industrial smart factories for customers. With an annual output of nearly 100 production lines, it is a high-tech enterprise, a member of the World Trade Center, and a member of national and provincial industry associations. So far, its outstanding performance and perfect after-sales service system have won unanimous praise from users.

We provide engineers with one-stop service of on-site measurement, design drawings, installation and training. Tailored to your special filling requirements. We provide one-stop service for engineers, including on-site measurement, design drawings, installation and training. Tailored to your special filling requirements.

Packaging process

Conventional raw material packaging

1. The surface is treated with rust prevention, 2. Inner plastic waterproof packaging, 3. Fix the outer layer with thick wood or steel frame, and then pack it with synthetic board. Combined container transportation, or separate container transportation. transport: 1. The standard plywood box body has better compressive strength and bearing quality. 2. The board area is small, the soil structure is good, and the leakage and water resistance are good. 3. When imported, the plywood box is free of fumigation, and the operation is simple.

Customer Photos

Our machines are located in many countries around the world, and we have a good reputation and end user satisfaction wherever our machines are located.

Exhibition customers

Dongtai has established a strategic alliance business relationship with partners all over the world in response to international demand. Its products are sold well in Europe, America, Southeast Asia and other countries and regions, and are received at home and abroad with "excellent quality, excellent service and reasonable price". Customers' favor.

Certificate

Certificate services:

All of our filling machine is made of superior spare parts,the processing line assembled strictly according to ISO9001regulation,so our equipment fully in accordance with the GMP&ISO standard production and passed CE certification.

FAQ

Q: How long will take for the delivery of product? A: 7 days for standard model, if machine in stock, will delivery immediately, customized model depend on customer requirements, usually about 30 days. To Q: What’s the insurance of after-sale service after purche? A: All our products, will be totally tested by QC department before delivery, with strict quality control process. The product is cost-effective during use, stable and reliable. One year warranty service for all machine, plee feel free to contact us if you have any questions. To Q: When the machine arrives at the work site, is it ey to install? How to solve the problem of quick installation and use? A: All machine model with installation video, to show the installation process more intuitively, and we will provide remote video technical support to solve your doubts and ensure that your installation is correct. Q: During the use of the machine, how to get after-sale service? A: We have professional foreign installation and commissioning engineers, which have many years of experience in foreign debugging with deeply recognized by customers. We will provide on-site installation and commissioning services for foreign customers, and we will guide your workers directly. To Q: Will the accessories change frequently with machine? A: The service life of the accessories is related to the daily maintenance. When ordering, we will give you free wearing parts and provide you with daily maintenance strategies.

Product Categories : Semi-auto filling machine > Liquid(oil)filling machine

Other Products

Hot Products

Three Side Seal Trailer Type Vertical Packaging Machine2016 Hot Sale Sachet Coffee and Suguar Horizontal Packing MachineVffs Horizontal Self-Support Bag Packing Machine (AH-180)Ah-500 Auto-Horizontal Pillow Packing MachineChain Bucket Packing Machine Semi-Automatic Packing MachineAutomatic Bread Cake Pillow Packing MachineAh-H100 Trough-Shaped Mixer Machine / (AH-H100)Ah-Cxj24 Bottle Washing Machine (AH-CXJ24)Automatic Powder Packing Machine (AH-FJJ300)Automatic Liquid Filling Packing Machine Beverage MachineAutomatic Ketchup Packing Machine Three Sides Sealing Machine (AH-BLT100)Automatic Semi-Fluid Packing Machine (AH-BLT-500)Automatic Powder Packing Machine, Flour Filling Machine (AH-FJJ100)Automatic Center Seal Bag Beans Packing Machine (AH-KLJ100)Automatic Water Pouch Packing Machine (AH-ZF1000)Automatic Sugar Stick Packing Machine (AH-KLJ100)